On Thursday, Front Range Community College, FRCC, and the Longmont Chamber of Commerce hosted a ribbon-cutting ceremony at the college’s Center for Integrated Manufacturing, CIM, marking significant advancements and achievements since its inception five years ago.

This milestone was not only acknowledged during the event but also served as a commemoration of the latest advancements at the CIM. Among these were the introduction of two new associate degree programs and FRCC’s active involvement in Colorado’s burgeoning Quantum Tech hub.

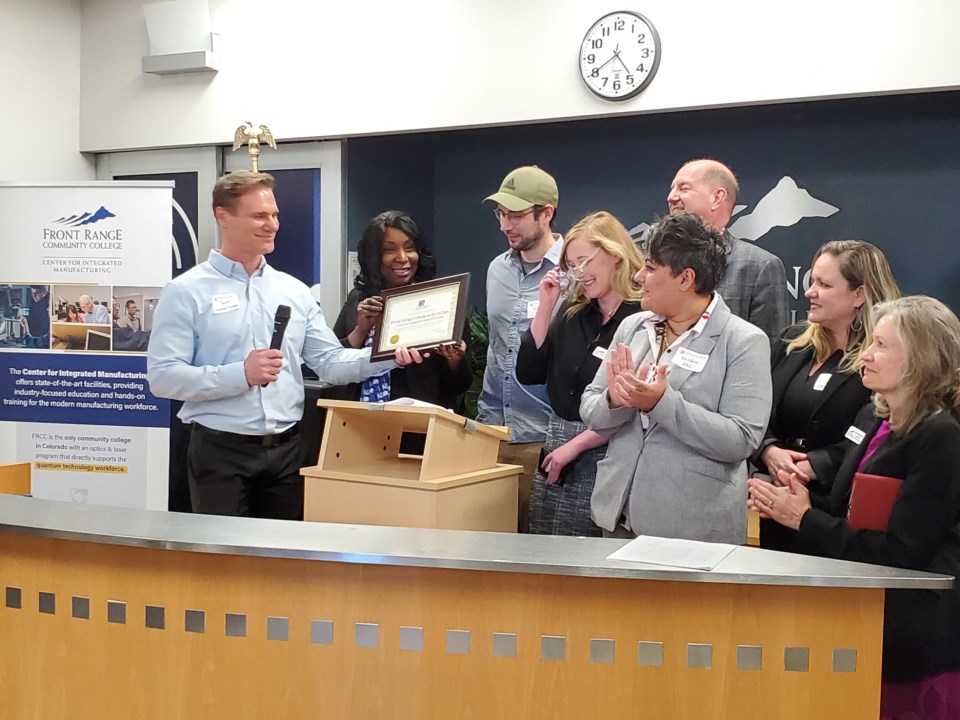

Moreover, FRCC’s recent designation as the Longmont Chamber’s “Legacy Business of the Year” for 2023 further accentuated the significance of the occasion, adding another layer of celebration to the event.

In the entryway of the CIM, enthusiasm unfolded as chamber members, FRCC staff, students and esteemed business partners converged. The atmosphere crackled with energy, palpable excitement whirling through the air like a gust from an industrial safety air gun. The atrium buzzed with animated conversations and laughter above a hum of machinery in the distance, every element of the space seemed to pulse with anticipation.

As the seconds ticked by, every eye was slowly drawn toward the front where the ribbon awaited its ceremonial severance, marking not just an opening, but a gateway to boundless possibilities.

“Today is such an exciting occasion where we celebrate the hard work and collaboration that has gone into creating this innovative space that continues to grow with the addition of our two new associate degrees. When we think about relevance in higher education, it doesn’t get any more relevant than a clear pathway to a job,” said the Academic Dean of Manufacturing, Automotive, Welding, HVAC & Construction Technology, Chris McGilvray.

FRCC President Dr. Colleen Simpson echoed this sentiment, emphasizing the significance of the CIM’s impact on the community and industry. Simpson also extended gratitude to the elected officials present, recognizing their vital role in supporting FRCC’s initiatives.

“We have invested in serving our manufacturing partners, industry and the community. We are part of a high-tech, hands-on learning,” said Simpson. “Advanced manufacturing is important, and we are here to build that workforce pipeline.”

Simpson further elaborated on FRCC’s commitment to apprenticeships, citing partnerships with industry leaders. Their initiatives aim to bridge the gap between academic knowledge and real-world demands, providing students with valuable hands-on experience. Simpson also shed light on FRCC’s collaboration with the Metallica Scholars initiative, which supports students pursuing technical careers.

Looking ahead, Simpson underlined FRCC’s commitment to staying at the forefront of technological advancements. She highlighted FRCC’s involvement in the Quantum Tech initiative, affirming the institution’s role in preparing students for emerging opportunities in the field.

“We are going to continue to be here to collaborate, to evolve, to be cutting-edge. And more importantly, we’re going to continue to listen to our industrial partners,” said Simpson.

The Program Director at FRCC’s CIM, Ken Floyd, shared insights into the center’s philosophy and approach to education. Floyd underscored the center’s commitment to hands-on training and industry-relevant curriculum.

“Our philosophy is hands-on center training, led by subject matter experts with decades of industry experience,” Floyd said

Floyd pointed out the center’s success in producing job-ready graduates who have seamlessly transitioned into the workforce and made significant contributions to their respective industries.

“I wanted to start this off by saying I opted for interpersonal communication instead of public speaking,” said Robert Thomas with a smile, an Electronics Engineering Technology graduate currently employed at Better Process LLC in Loveland. “I owe everything to being here. I wouldn’t have had the tools that I needed to do what I do at my job.”

As the event drew to a close, attendees spilled outside to the front of the building, united in a shared sense of accomplishment and excitement for the future. Gathered beneath the bright Colorado sky, the crowd erupted into applause and cheers as Simpson stepped forward to cut the ribbon, symbolizing not just the opening of a facility, but the dawn of a new era in manufacturing education and industry collaboration.