Tyler Knapp and Alex Conrad found a new home for their creative and inquisitive natures in the Center for Integrated Manufacturing at Front Range Community College's Longmont campus.

Knapp and Conrad, both 24, are students of the center’s precision machining technology program, which teaches them how instruments work in fields as diverse as aerospace, automotive and computers.

“Being a machinist allows you to be practical and creative at the same time,” Conrad said. “You get to take things apart, find out what they do and put them back together again. It’s what I always wanted to do.”

“It’s definitely not the same thing every day,” added Knapp.

And last month they got back in the classroom to keep learning.

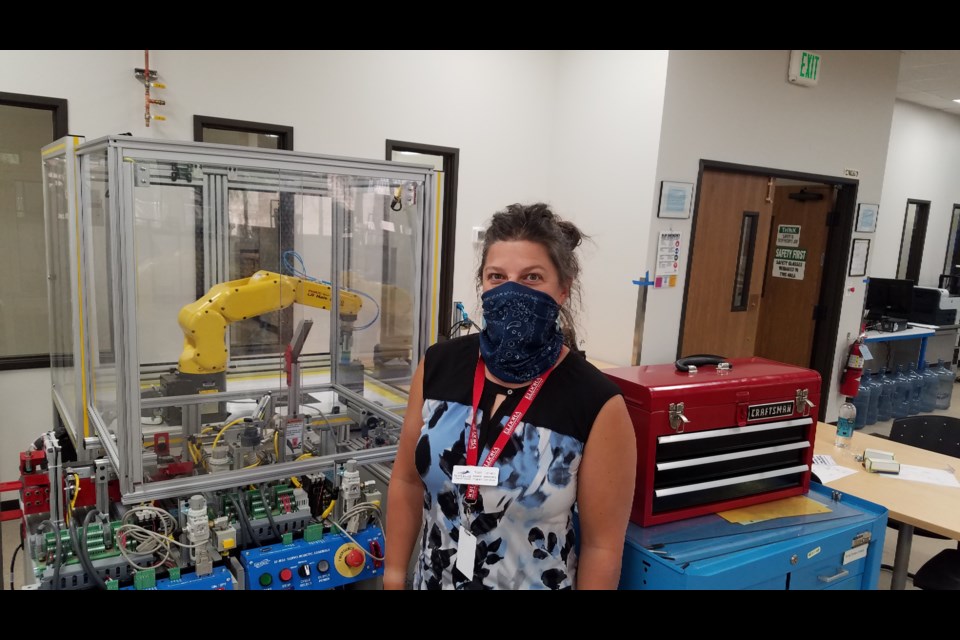

COVID-19 prompted the center to shut down in March and start up again in June. Nearly all the 75 or so students enrolled at the facility returned in June to finish out their programs, said Nicole Gervace, FRCC’s assistant director of manufacturing technology.

George Deeb, lead faculty member at the center, said closing the campus made sense since all the courses required a hands-on approach that can’t be duplicated during a Zoom class.

“The learning pretty much demands that you have to be here,” Deeb said, noting everyone wears masks and are socially distanced while they work.

The 27,000-square-foot center also is a career launching pad for Knapp, Conrad and 20 or so other students enrolled during the summer semester at CIM. The nearly year-old facility is a mixture of sitdown lectures with state-of-the art labs that demand meticulous work and attention, just like any employer demands in the outside world.

CIM is the only college facility in the state with four advanced manufacturing programs under one roof, according to FRCC officials. The core courses are automation and engineering technology, electronics engineering technology, optics technology and precision machining.

Officials hope the learning at the center will produce a stream of savvy workers to answer the growing need for high-tech manufacturing jobs in Colorado.

The state expects to have 5,000 new jobs in manufacturing by 2026, according to FRCC. But local industries often can’t find enough workers with the proper skills and training to fill even entry level jobs that pay $20 an hour, according to the college.

“A lot of people who come onto the jobs didn’t even know how to read a tape measure,” Gervace said. “The companies often had to start from scratch, teaching students about their new jobs.”

To help students meet their financial needs and graduate from CIM, the Ball Foundation — the philanthropic arm of Ball Corp. — last month donated $50,000 to the Front Range Community College Foundation to support 25 to 40 students enrolled in the four advanced manufacturing programs.

Chris Chavez, executive director of the Ball Foundation, at the time of the donation said Ball is a huge supporter of the center since it will bolster science, technology, engineering and math, or STEM, education in the state.

“STEM education is a core funding area for Ball, and we work together with strong community partners like FRCC to address workforce needs in STEM industries,” Chavez said

One of the big pulls of earning an associate degree or certificate at the center is entry-level pay in most of the four fields is impressive. Entry level workers can earn $30,381 in precision machining technology to $51,552 a year as an electrical and electronics technician.

People starting out at automation and engineering technology can begin at $68,000.

Conrad is happy with his choice of being a machinist.

“I realize robotics is cool,” Conrad said. “But what I like to do is figure out what is going on inside of a robotics arm. Take it apart and see how it works. That’s kind of my nature.”